AS100 Safety Utility Knife

Why Safety Professionals

Prefer the AS100

Why Safety Professionals Prefer the AS100

Safety Knives For A Safer Workplace

Patented Safety Features

Minimize risk of lacerations during handling and storage.

Built for Durability

Handles are ambidextrous and ergonomic. Blades are made of steel for longevity. Finger holes with soft touch polymer for comfort.

Highly Visible Green

Ensure a safety knife is never misplaced again.

Ideal For All Materials, Including

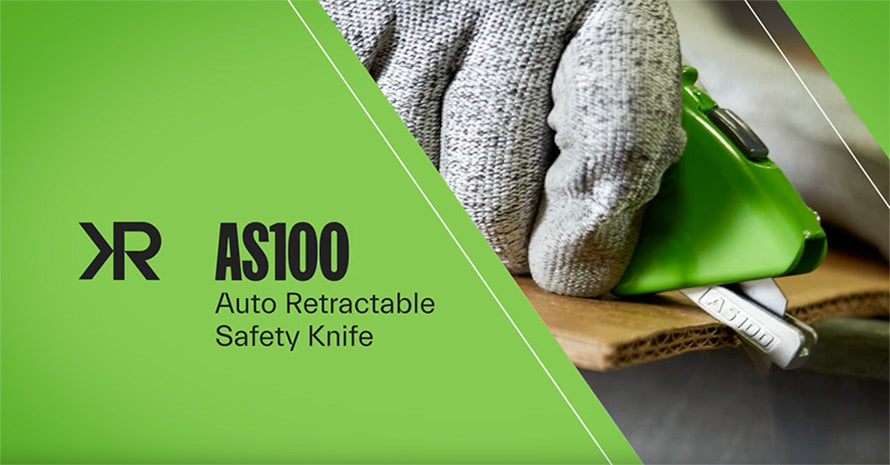

AS100 Auto-retractable Safety Knife

Innovation meets safety and durability, with the AS100. This ergonomic safety knife was developed in partnership with safety professionals to set the standard for automatic safety knives in the industry. With over 1 inch of blade extension, the AS100 can safely cut heavy-duty materials such as double or triple wall corrugated, heavy-duty rubber, and difficult-to-cut plastic bands. It also excels for slabbing paper, film or foil.

Equipped with fast-acting Riteknife Blade Guard Technology™ to prevent lacerations, and a patented, easy tool-free blade change, you can feel confident that every feature has been designed to eliminate risk of lacerations and repetitive motion injuries.

Product Specifications

Cutting Depth

25 mm

Weight

150 gms

Dimensions

180 mm x 55 mm x 19.5mm

Materials

Heavy duty aluminum

AS100 Accessories

AS100 Straight Blade

Each low profile AS100 blunted tip Mozart blade greatly reduces friction and is set at the optimal angle for easy cutting.

AS100 Hook Blade

Blunted tip blade with low profile minimizes the force needed to pull through and the resulting repetitive motion injuries this often generates.

AP100 Holster / AP50 Holster

Makes it easy to keep an automatic safety knife ready for use. Also holds pens, markers spare blades and the CB100.

How to Use the AS100

Safety and Quality Go Hand in Hand

Frequently Asked Questions about the AS100 and Auto-retractable Safety Knives

Why use an automatic retractable safety knife?

If you have a utility knife, it's important to keep safety in mind. This safety utility knife is a reliable tool because the guard will lock in place automatically over the blade after the cut is finished.

This makes factories and loading docks safer and more productive—you don't need to worry about cutting your body on an unguarded blade.

What is the blade extension?

25 mm

How does the safety feature work?

Once cutting is complete, the guard lock will automatically activate. It must be squeezed to be released.

Do you need any tools to change the blade?

No, just pull up the release lever

Why is the blade blunted?

To prevent accidental punctures

Can the AS100 be locked?

Yes, slide the side button forward to lock

Is the AS100 ambidextrous?

Yes

What is the AS100 made from?

Heavy duty aluminum

What does the AS100 cut?

The AS100 can cut single, double, and triple wall corrugated cardboard, heavy-duty rubber, stretch-wrap, plastic banding, gasket material, paper and plastic bags and is great for slabbing material off a roll.

What is a safety knife?

A safety knife is a type of knife that has special features such as protective guards, auto-retractable blades and blunt tips These tools are used to prevent lacerations and repetitive motion injuries.

Why are safety knives important?

Safety knives are important because they can help you avoid injury and make your work easier. Safety knives are designed to protect both the user and others around them from injury. If you have a regular knife instead of a safety knife, then there's a chance that someone could get hurt by accident if their hand slips while they're using it.

Why is it important to combine training with your safety knife purchase?

The importance of combining training with your safety knife purchase is that it helps you learn how to use your new tool in a safe and effective manner. When your employees are trained on how to use their new safety equipment, they will be able to perform their jobs safely and confidently.

How do safety knives protect people?

Safety knives protect people by making sure they don't cut themselves. The sharp edge of a regular knife can easily cut someone's skin and cause serious injury, but safety knives are designed to prevent this type of accident.

How do I evaluate which safety knife is most effective for my organization?

The best way to evaluate which safety knives are best for your cutting tasks is by conducting a free safety knife evaluation and discussing your specific situation with a safety cutting professional.

What are common injuries caused by unsafe knives?

The two most common injuries caused by unsafe knives in the workplace and in factories are lacerations and repetitive motion injuries.

Lacerations are the most common injury caused by unsafe knives in the workplace. These occur when a person's body comes into contact with a blade that is being used.

Repetitive motion injuries are also common with poorly engineered knives in the workplace. These occur when someone uses a knife repetitively for long periods of time.. This can lead to carpal tunnel syndrome, tendonitis, or other musculoskeletal issues.

Contact

Our experts are here to help you find the Riteknife that fits your needs and goals.