The AS100 Automatic Safety Knife is the optimal cutting tool to slab material off a roll. The durable ambidextrous, aluminum housing is made to stand up to the toughest industrial tasks and can be pulled or pushed to safely slab paper or plastic off a roll. The soft touch rubber trigger mechanism and easy tool free blade change make this knife a favorite with end users. The low profile blade makes for easier cutting. The safety guard locks into the safe position after the blade loses contact with the material being cut; simply squeeze the trigger to initiate another cut.

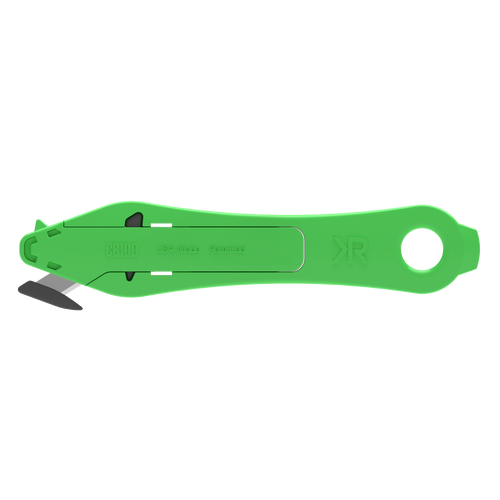

The CB100

Concealed Blade Safety Knife

The CB100 has a concealed blade to prevent injury when it's in use.

Developed with and for safety professionals, the CB100 is the ideal multi-purpose safety knife.

The CB100's ergonomic ambidextrous handle, with easy tool-free blade change and guarded blade technology, avoids blade edges coming in contact with skin.

Riteknife Flowthrough Technology™ minimizes friction and maintains optimal blade angle to eliminate repetitive motion injuries and lower the force needed for cutting.

The molded tape splitter allows for easy penetration into clear packaging tapes as well as fiber-reinforced box tapes.

Product Specifications

Cutting Depth

5.8 mm

Weight

30 gms

Dimensions

175 mm x 40 mm x 6mm

Materials

Glass-filled nylon

AS100

Automatic Safety Knife

The AS100 has a retractable blade that retracts when the knife is closed.

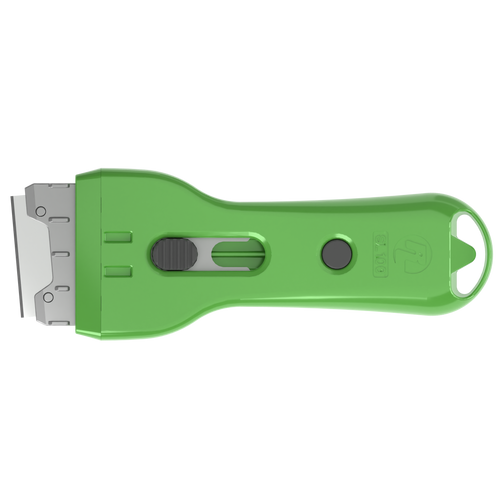

The world's first true safety scraper.

Designed with a spring-loaded mechanism, the blade within the SL100 sits safely within an ergonomic handle, after each cut. The mechanism has a patented design to prevent the push-back force from being transmitted through the scraper to the user's thumb.

With the SL100's spring-loaded safety technology, you will feel confident that you're protected from injury—and frustration. As with our entire line of safety knives, the SL100 is fitted with Mozart® blades, which are known for their longevity and durability.

Product Specifications

Cutting Depth

25 mm

Weight

150 gms

Dimensions

180 mm x 55 mm x 19.5mm

Materials

Heavy duty aluminum

Frequently Asked Questions

What are the different types of corrugated?

Corrugated board comes in three different types: solid flute (SF), wavy flute (WF), and cross flute (XF). Each type has different properties depending on its intended use: SF is stiffer than either WF or XF boards; WF boards are flexible enough for folding into corners; XF boards have more strength than either SF or WF boards.

What are different types of corrugated used for?

Single-wall corrugated, used for most boxes, is much thinner than double-wall, and it tends to be used for lighter-weight packaging products. Double-wall corrugated has more structural integrity than single-wall and can be used for heavier products or those that need more protection during shipping or storage. Triple wall is used to contain very heavy products that are transported on skids.

What is a safety knife?

A safety knife is a type of knife that has special features such as protective guards, auto-retractable blades and blunt tips These tools are used to prevent lacerations and repetitive motion injuries.

Why are safety knives important?

Safety knives are important because they can help you avoid injury and make your work easier. Safety knives are designed to protect both the user and others around them from injury. If you have a regular knife instead of a safety knife, there's a chance that someone could get hurt by accident if their hand slips while they're using it.

Why is it important to combine training with your safety knife purchase?

The importance of combining training with your safety knife purchase is that it helps you learn how to use your new tool in a safe and effective manner. When your employees are trained on how to use their new safety equipment, they will be able to perform their jobs safely and confidently.

How do safety knives protect people?

Safety knives protect people by making sure they don't cut themselves by engineering out the hazards. The sharp edge of a regular knife can easily cause serious lacerations. Safety knives are designed to prevent this type of accident.

How do I evaluate which safety knife is most effective for my organization?

The best way to evaluate which safety knives are best for your cutting tasks is by conducting a free safety knife evaluation and discussing your specific situation with a safety cutting professional.

What are common injuries caused by unsafe knives?

The two most common injuries caused by unsafe knives in the workplace and in factories are lacerations and repetitive motion injuries.

Lacerations are the most common injury caused by unsafe knives in the workplace. These occur when a person's body comes into contact with a blade that is being used.

Repetitive motion injuries are also common with poorly engineered knives in the workplace. These occur when someone uses a knife repetitively for long periods of time. This can lead to carpal tunnel syndrome, tendonitis, or other musculoskeletal issues.